About Us

Who We Are?

We are a fully integrated solution providers in the Indian flexible packaging sector. Commitment to research and innovation in the field of flexible packaging began in 1985. This commitment has been the driving force behind the innovative products that have been manufactured over the year's establishing Ridhi Petrochem as a forerunner of industry development and a leading player in the domestic & international markets.

Our Reputation

done_all Leaders in Wide Web Holography films & registered Holography Laminates

done_all First to introduce low cost printable metallizable grade of Cast Polypropylene (CPP)

done_all Among the first to introduce Polyolefin Plastomer POP & Metalocene in India

Snapshot

done_all Established in 2005 ; an industry presence with edge as we produce our own CPP

done_all A pioneer in packaging industry, offering quality solutions in flexible packaging including security packaging

done_all Headquartered in Mumbai and having state-of-the-art manufacturing locations in Umbergaon, Gujarat.

done_all An established customer base across the industry spectrum

done_all Close proximity to the major raw material and consumption centers

done_all Foraying into Export with clients of very high repute in UK, Europe & Africa

done_all 250 employees across; ahighly qualified R & D and product development team

What makes flexible packaging attractive?

done_all Lack of alternatives - Materials like metals are volatile; Glass is becoming increasingly expensive; Wood is non eco-friendly

done_all Great opportunities for outsourcing to emerging nations

done_all High barrier High performance pouches are also becoming stronger players in seafood, rice, wet pet food, andready- to -eat meal applications

done_all Changing Consumer habits in 1,2 & 3 Tier cities with working style of fast economies like developed countries globally, therefore making life on a fast track. Thus impetus given on easy, fast, convenient and flexible products, which is the prime deliverance of FLEXIBLE PACKAGING.

Major demand drivers for flexible packaging

done_all Quality consciousness amongst buyers

done_all Promising economic growth & Increasing purchasing power

done_all Deeper market penetration due to Unit pricing policy followed by FMCG Cos & MNCs.

done_all Emergence of newer market segments such as ready to eat fast food in flexible packages

done_all Accelerated growth of rural economy with tilt towards branded packed products

done_all Rampant growth in online shopping is likely to give further impetus to packaging industry

done_all Large export markets- as India is low cost producer compared to manufacturers in Europe and USA

Where are we headed to

done_all Various Capex undertaken & completed over last few years. Total converting capacity of over 24,000 metric tons annually.

done_all New Greenfield projects in planning at different locations to service clients with ease, & establish buy-for-usage model to minimize their inventory.

done_all Exploring opportunities for availing outsourcing of flexible packaging requirement from giant global players to help them achieve low-cost hi-quality material. Thus is process to apply for higher standards of good manufacturing practices like BRC-IOP etc.

done_all Becoming synonymous with packaging domestically & globally by offering array of solutions & services to widen clientele base.

done_all Achieve self-sustenance by developing a unique work culture model wherein every aspect of the growth drivers are supported and effectively implemented to back-up our unanimous goal of building a sustainable, profitable, growth-oriented, technology-adaptive, socio-economic conscious, and positively progressive organisation.

done_all Developing “Can-do” attitude through-out the hierarchy to further strengthen our mission to become a partner of choice for all your packaging needs.

Our Journey Brick by Brick

Manufacturing Competence

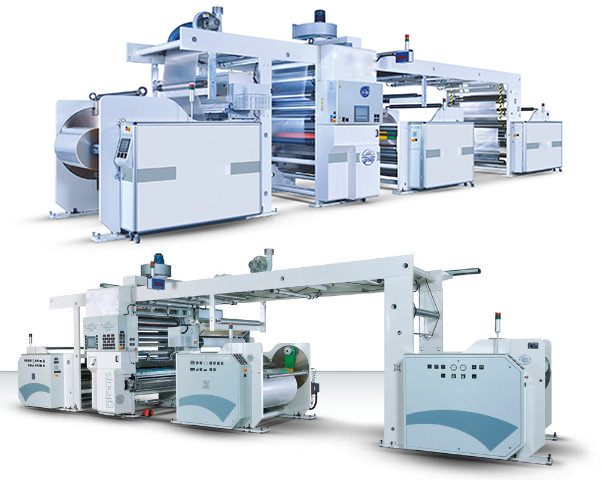

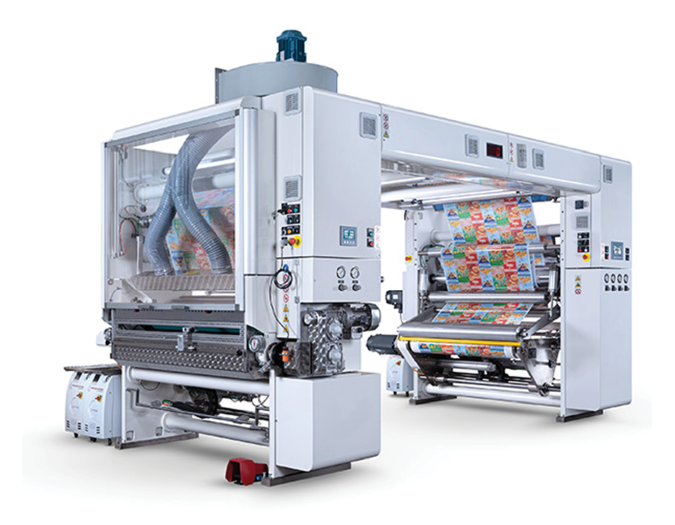

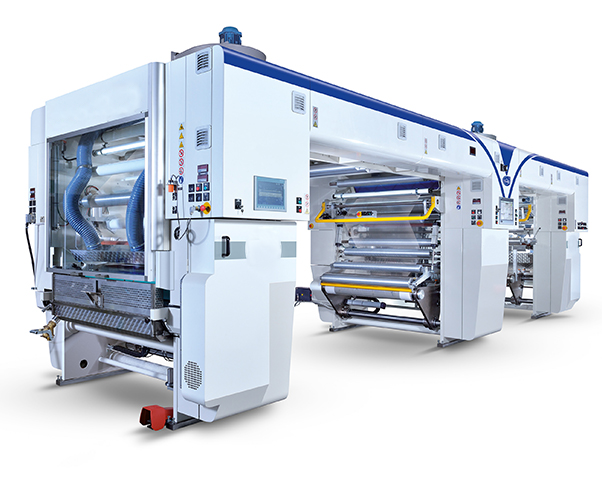

done_all Printing facilities up to 10 colors of European makes with Rotogravure & Flexo technology

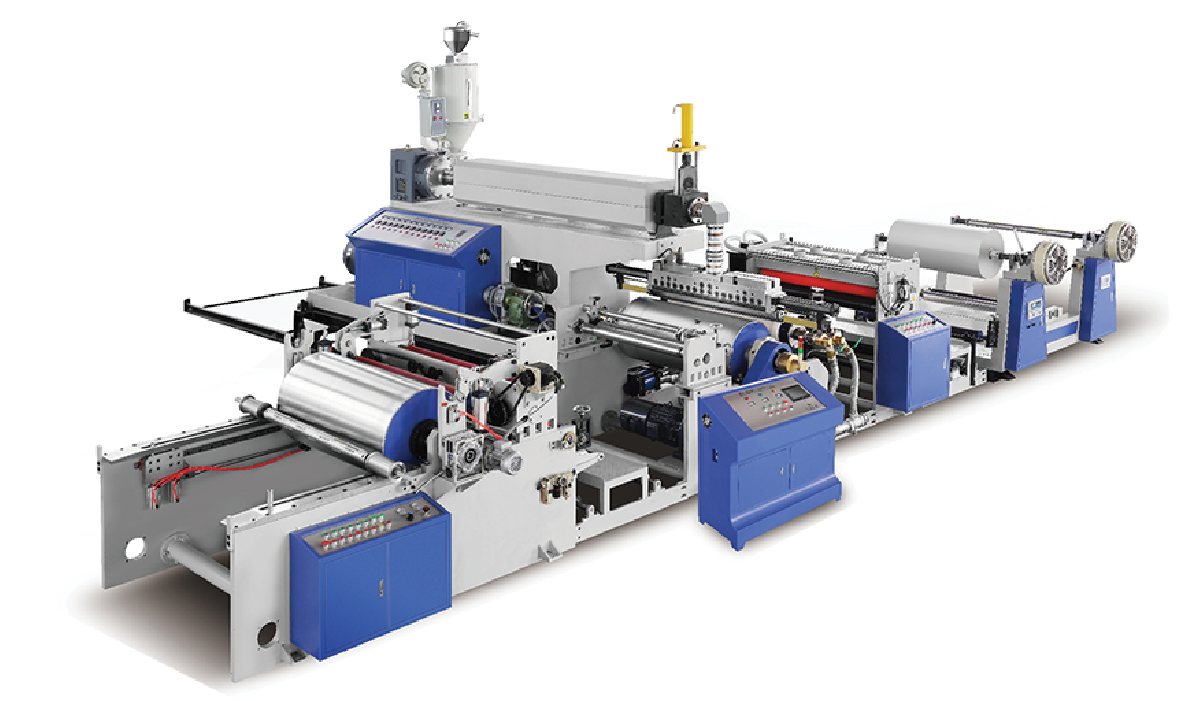

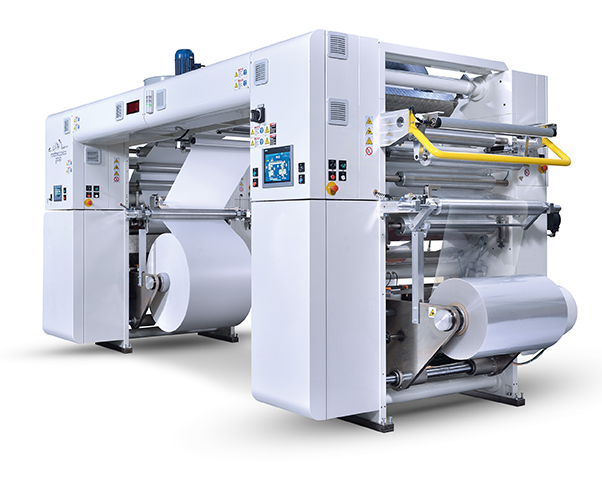

done_all Lamination and specialized coating systems with Solvent based, Solvent less, water based and latest Extrusion Lamination technologies

done_all Multilayer Extrusion facilities in Cast (CPP, EVOH, EVA) & blown technologies

done_all Advanced Holographic plant from Italy with Hot & Cold Embossing Machines

done_all High Speed Slitters in various numbers from different origins

done_all Accurate flat bed stamping foil & rotary hot foiling technology

done_all High Speed, high quality, low thickness, multi-layer co-ex extrusion lamination & coating facility from renowned Global Technology provider.

Awards

Acknowlegment We Received

120

Happy Clients

200

Projects

20

Years of Experience

3

Awards